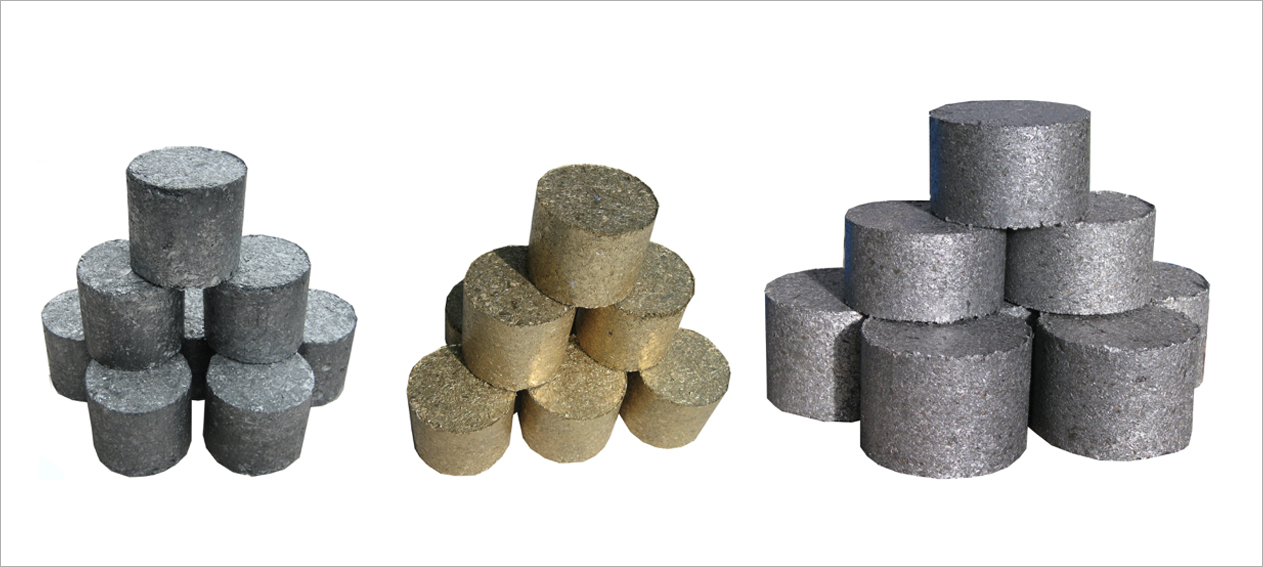

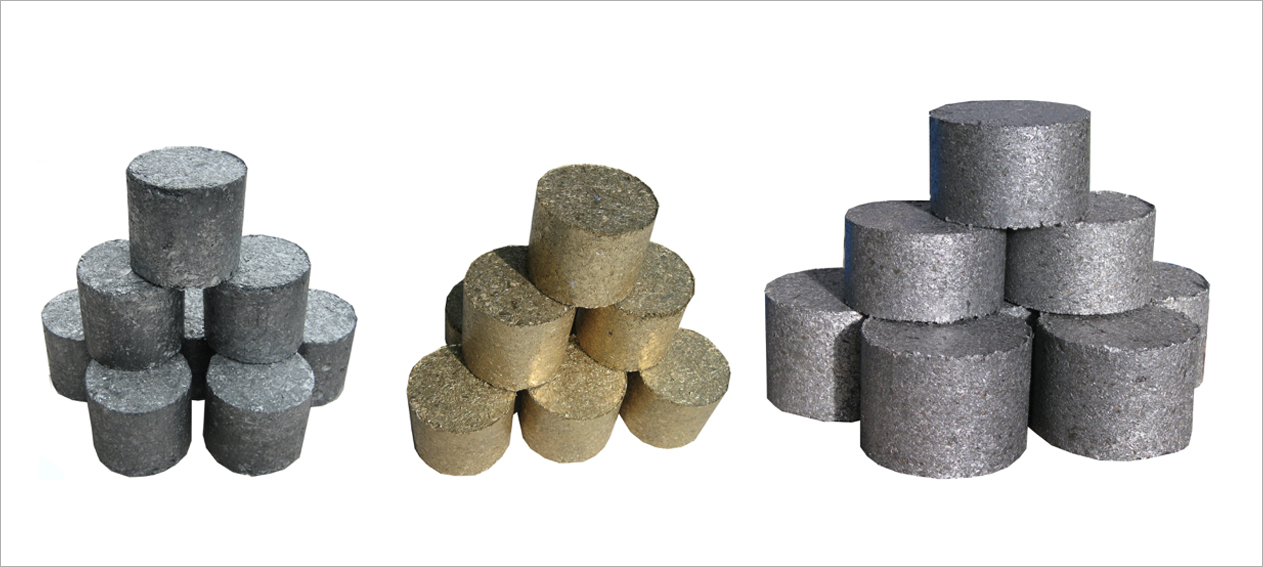

The briquetting machine uses a hydraulic drive to squeeze the liquid metal chips with high pressure, squeeze and separate the liquid in the wet chips, and compress and shape the metal chips. To realize the recycling of coolant, the chip reduces the storage and transportation space, and the chip reduces the ablation rate when it is returned to the furnace for melting and casting.

The metal chips are pushed to the pre-compression chamber by the feeding screw. The pre-pressurized mold driven by the hydraulic cylinder pre-compresses the wet chips. Then the main hydraulic cylinder pushes the main pressure mold to squeeze the chips at high pressure. Wet chips are separated here, and the chips are compressed into high-density blocks. The reversing machine displaces the briquette horizontally, and the rod pushes the blocks out of the briquetting machine.

The metal chips are pushed to the pre-compression chamber by the feeding screw. The pre-pressurized mold driven by the hydraulic cylinder pre-compresses the wet chips. Then the main hydraulic cylinder pushes the main pressure mold to squeeze the chips at high pressure. Wet chips are separated here, and the chips are compressed into high-density blocks. The reversing machine displaces the briquette horizontally, and the rod pushes the blocks out of the briquetting machine.

Product Feature:

★ Heavy-duty structure, strong and reliable

Product Feature:

★ Heavy-duty structure, strong and reliable

★ The hydraulically driven pre-compression structure ensures high-density compacts

★ Reasonable layout of each component and compact structure

★ The mold is made of high-strength wear-resistant material and special processing

★ Automatic block arrangement, no need to configure a block arrangement machine.

★ Universal components adopt world-class products of the German system